As many will know, and as has already been explained in other articles, there are 2 main types of furnaces: those in a controlled atmosphere and the vacuum ones, it’s clear how the concept of atmosphere, as discriminative for categorization, has great importance.

The choice of the atmosphere to be used in a furnace is very important and must be made in function of the heat treatment that you want to implement. In general, the atmosphere may be chemically inert (does not interact with the surface of the product during the process) or chemically reactive (will react with the product during the heating process). The chemical elements which are normally used to constitute the atmospheres of the furnaces are the following:

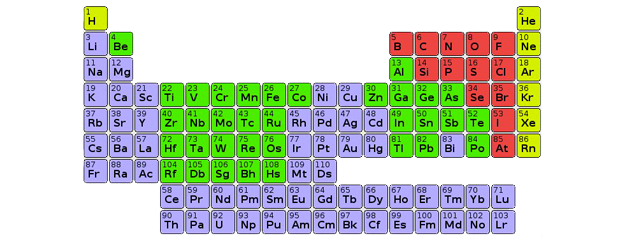

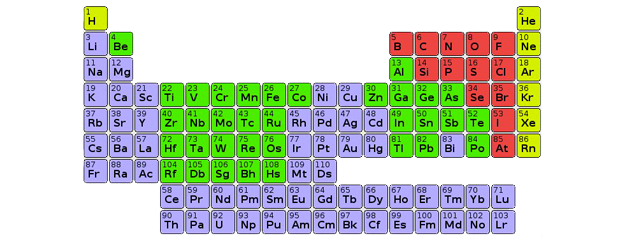

- Molecular nitrogen (N2): Inert to iron for which it is used for steels with low carbon content.

- Atomic Nitrogen (N): is not considered inert because it combines with the iron.

- Hydrogen (H or H2): reducing gas , can be used to prevent oxidation of the iron.

- Oxygen (O2): oxidizer gas.

- Water vapor (H2O): Effect oxidant due to the component of oxygen.

- Carbon Dioxide (CO2): Effect oxidant due to the oxygen component , even for the steel.

- Carbon Monoxide (CO): Gas reducing , very stable at high temperatures.

- Hydrocarbon: fuel gases used to supply carbon to the atmosphere.

- Ammonia ( NH3): Used to make nitrogen atmosphere.

- Steam: Used to produce a protective oxide on the surface of the products due to the reaction of oxygen with the iron content .

- Argon (Ar): gas is totally inert .

- Helium (He): gas is totally inert .

As is clear from this list, the choice for those who must manage the atmosphere of the furnace is large enough and should be studied carefully depending on the type of work involved.