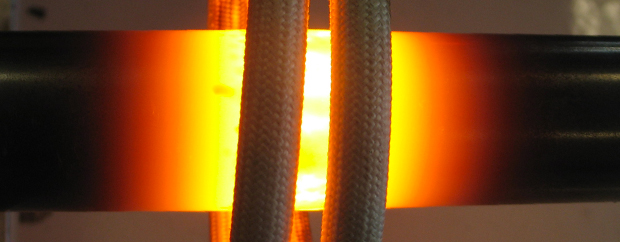

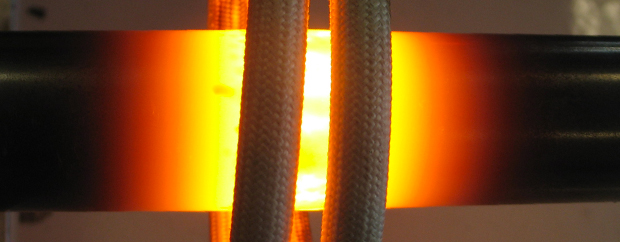

Induction heating has long been used in numerous industries for various applications but it is a novelty in the world of welding, just recently it has become quite common to find where processes are carried out in industrial welding.

The process has brought some benefits to the welding processes, such as a substantial improvement of the sites of welding because the heat does not directly affect the metal but takes a warm-up “from within.” More similar to a microwave oven that a pot on a stove.

This procedure is possible due to the electromagnetism high frequency that is able to shake the molecules of the metal by increasing the temperature. Another substantial advantage is the modularity of the heating, it is in fact possible to heat precise depth of the material by varying the frequency of the projected field. This will also reset any heat loss typical of the classic method for direct heating. Even in terms of time, the induction heating is better as compared to classical methods, it is possible to save up to 50% of the time spent on each cycle by combining it with other techniques.