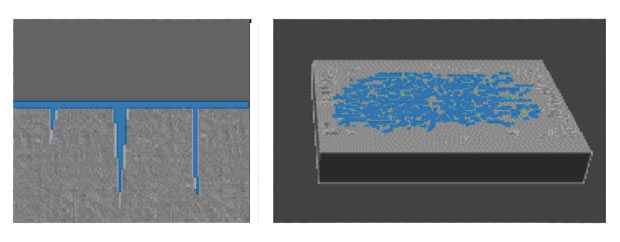

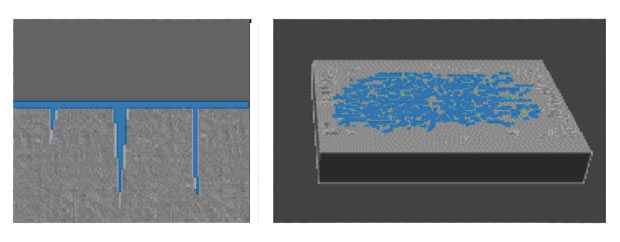

This kind of test is used to determine the surface defects of metal alloys, pure metals and some non-metallic materials. Due to these characteristics of ductile and broad spectrum of application has become one of the most used methods to verify these imperfections.

The test consists of the following: is sprinkled evenly over the surface in question a solution of a visible element (defined ink) in an aqueous base or solvent, this is left to penetrate the surface for a certain period of time after which it is removed and is applied a developer who goes to react with the ink bringing to light areas in which it is penetrated. This will only occur at the penetration of micro-cracks, overlaps and porosity.

The parameters to be considered during this type of test are:

- Clean the test surface

- Sufficient time for permeation of the penetrant

- Application Developer time

- the macroscopic surface inspection for detecting discontinuities