CRP Technology has created the supporting structure of a nano satellite.

Italy (CPR Technology is from Modena) again occupies a position of extreme importance in the Additive Manufacturing Industry.

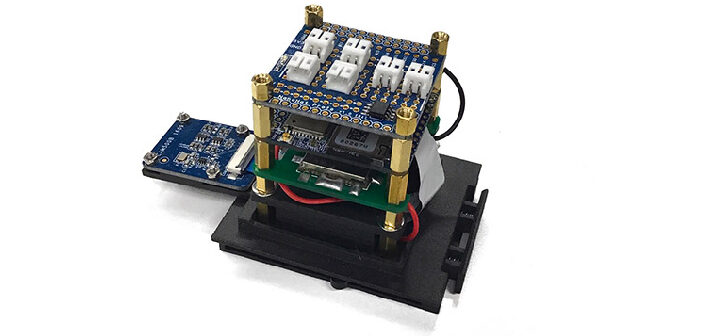

The nano satellite is small in size, a cube of about 5 centimeters per side and weighing less than 250 grams.

The Italian structure and components are 3D printed with composite materials and there are three functional prototypes of nano satellite, two of which are for testing and one for flight in orbit.

There is still a lot of work to be done, of course, to arrive at a massive use of professional 3D printing for nano satellite, but the experience of the Italian company is certainly a key point for the future.

It is the first time that entire functional 1P PocketQube prototypes are ready for engagement in space and are made using a composite material reinforced with carbon fiber, Windform® XT 2.0 and a selective laser sintering process.

Given the small structure of the nano satellite, the challenge was to be able to adapt the electronics, the video camera and the radio system inside.

To date, given the size of the construction, the nano satellite built represents the best that can be built and built for the remote sensing of the earth’s resources.

The American Mini Cubes’ project for this nano satellite arises from the need to have a viable alternative to CubeSats whose launches in orbit are becoming increasingly expensive.

Joe Latrell, founder of Mini Cubes, specifies: “We have done several tests, and we will do more. So far we have tested the load at +20 kg. Windform® XT 2.0 has been subjected to vibration tests according to NASA GEVS-7000 specifications, to the vacuum test to simulate conditions in the Earth’s orbit and has been thermally tested from + 50 ° C to -40 ° C. Windform® XT 2.0 has passed all the tests we have performed.

Our next step is to test the nano satellite in orbit and launch it in the second quarter of 2021. This will be the final validation for our engineering process. “